Face Area Haulage

With virtually all main coal haulage systems within

the seam being by conveyors which start from a more or less fixed point, some

arrangement is needed to bridge the gap from the coal cutting machine to that

point.

For a longwall face the gap is bridged by the AFC and

BSL, both of which are dealt with under longwall equipment and will not be

discussed here.

For other mining systems, a more flexible arrangement

is required as coal has to be transported from other roadways back to a fixed

point, with frequent changes of the mining location. By far the most common

method of transport at present is the use of "shuttle cars".

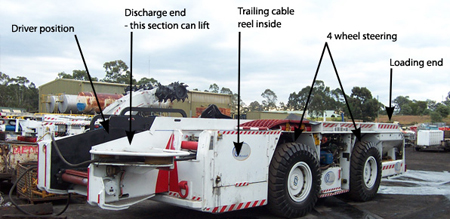

Typical shuttle car viewed from discharge end.

Trailing cable connects to closest corner, driver located on opposite side

Shuttle cars are electric powered, rubber tyred

vehicles - essentially a large trough with a scraper conveyor running along the

floor, a driver's position mounted to one side and a jib section at one end of

the conveyor which can be raised for discharging the load. They are four wheel

steered, four wheel driven vehicles with power supplied by a trailing cable

reeled onto and off a cable reeler mounted opposite the driver's position.

It is normal for two cars to be used in one mining

section with one car being loaded by the continuous miner at the face while

the second car is discharging its load at the conveyor. Whilst being loaded,

the scraper conveyor in the shuttle car is run in short bursts to drag the load

towards the opposite end of the car until the car is full. That car then heads out

to the conveyor discharge point, passing the other car at a shunting position

on the way.

On reaching the conveyor, the unloading jib section is

raised to enable coal to be discharged into the "breaker feeder" or directly onto the conveyor (depending on

the mine's relevant equipment and practices) and the scraper conveyor is run

until the car is empty. This car will then return to the mining machine or to

the passing shunt to await the other car.

Shuttle cars have proved to provide a robust, flexible

and generally reliable haulage system and are still very popular. They do

suffer from a number of disadvantages:

-

Trailing cables are prone to damage as a

result of being run over, squashed against the ribs or other equipment or

jammed and pulled apart and can be a safety hazard as well as a common source

of downtime.

-

Trailing cables essentially restrict the

number of cars servicing a miner to two, without a risk of tying the cables in

knots.

-

The haulage is intermittent (unless a car

is used as a temporary bunker behind the continuous miner).

-

The distance between the mining face and

the conveyor discharge point is limited by the length of the trailing cable,

unless other special arrangements are adopted.

Other equipment has been developed to try and overcome

some of these problems:

-

Battery powered shuttle cars were developed

to avoid trailing cables and provide more flexibility; some success and

certainly more flexible, but batteries are bulky and heavy and require time to

charge up and cool before use – this entails a charging station and

battery changing equipment. All of this can be just as troublesome and

hazardous as using cables, so is only beneficial if the extra flexibility is

required.

-

Diesel powered shuttle cars were similarly

developed to avoid the use of trailing cables and provide more flexibility;

certainly more flexible than either cable or battery powered cars and haulers

and are unrestricted in respect to distance between loading and discharge

points. Their biggest drawback is the production of diesel fumes and heat in

the face area which can create unpleasant conditions even with good

ventilation.

-

Another development has been the use of "ram

cars" or "haulers" in place of shuttle cars: these are

articulated vehicles with one end carrying the power system and the driver

position, the other end consisting of a large tray or bin with a push plate to

eject the load. The push plate is operated by a hydraulic cylinder. Ram cars or

haulers are operated similarly to shuttle cars except the cars have to be

turned between the loading and discharge locations, loading and unloading being

at the same end of the vehicle. Ram cars/haulers are usually diesel or battery

powered.Neither of these systems have received wide acceptance to date.

-

Flexible conveyor trains; various types

have been produced including both floor mounted and roof mounted continuous

conveyor systems with both systems offering some degree of operational

flexibility. The discharge end of the flexible conveyor runs above the end

section of the main conveyor to enable the flexible conveyor to discharge onto

the panel conveyor as the flexible conveyor follows the continuous miner

through the development sequence, The face end of the flexible conveyor is

attached to the rear of the continuous miner or is self propelled and kept at

that position. With such an arrangement the flexible conveyor is always in

place between the miner and the main conveyor, providing continuous haulage.

The main disadvantage to date is the high capital cost of such systems and the

high maintenance costs associated with the flexible belting. The flexible

conveyor trains, at this stage, cannot handle right angle bends and necessitate

formation of diamond shaped pillars, which may in some circumstances be prone

to crushing on pillar ends and/or result in larger intersections than otherwise

preferred. Some mines also consider that the angled cut-throughs that result do

not suit most other aspects of mining. Both roof and floor mounted flexible

conveyor systems were trialed in Australian mines during the late 1980's with

limited success. However there is now a resurgence of interest in these systems

as mines seek to improve gate road development rates,

-

Bridge conveyor systems: again various

types have been produced including both chain type conveyors and conventional

conveyor belt systems. Bridge sections are typically short (6m on conveyor

bridges and 16m on chain type bridge systems) and are self propelled (the

conveyor bridge systems are now fitted with PLC controls which enable the

entire system to be operated by one person whereas the chain type require an

operator on each bridge section). Again angled cut-throughs are preferred (70o)

to facilitate transition between adjacent roadways. Depending upon seam (and

hence mining) height the discharge end of these systems can either run over or

beside the main conveyor to enable the bridge conveyor to discharge on the

panel conveyor as the bridge conveyor follows the continuous miner through the

development sequence. Both bridge systems provide a continuous haulage system

similar to the flexible conveyor train systems while both have only recently

been introduced into Australian mines (although a chain type bridge system was

operated in one Australian mine during the 1990's with limited success)

With all the car or hauler arrangements, some fcaility

is needed to load efficiently at the panel conveyor. At least a "boot end" is required, a trough arrangement with a

top opening slightly narrower than the conveyor belt. The return roller for the

conveyor is at the end of the boot nearest the face, so the belt runs under the

opening in the top of the boot to carry the coal away. The coal can be loaded

on top of the boot, the pile reducing at the rate that the belt can remove the

coal. Care is therefore required to ensure that loading is not too fast

otherwise spillage will occur. The belt will be fully loaded whilst there is

coal left in the boot.

A better means of transferring the coal from car to

belt is to use a "breaker feeder". This is a large hopper fitted with a scraper

conveyor in the floor leading to a narrow outlet, approximately the width of

the conveyor belt, and often containing a coal breaker at the outlet. The use

of a feeder enables the car to discharge at maximum rate while the feeder

controls the feed rate onto the belt to the desired rate. This is particularly

important as high shuttle car discharge rates have been proven to result in

higher development rates, whilst controlled feed out rates from the feeder will

prevent overloading of the conveyor and the ensuing spillage. While the breaker

on the feeder may not be as effective as a crusher in reducing product size,

they are generally effective in breaking large lumps of coal or stone into more

manageable sizes and improving conveyor loading.

Flexible conveyor trains and bridge conveyor systems

feed directly onto the panel conveyor and obviate the need for a breaker feeder.

Recent trials with both systems do however highlight the need to introduce a

capability to size any large lumps that may be produced if high productivity

levels are to be sustained. This can be done either by fitting an in-line

breaker into the throat of the continuous miner discharge boom or onto the

first bridge section behind the continuous miner.